Relentless Pursuit of System Optimization and Engineering Excellence does not apply to Carbon Capture

Failure is an Option

Relentless System Optimization

One of engineering's most basic instincts is to break hard problems into simpler, smaller problems. When working with energy-intensive problems, a common-sense approach to improving energy efficiency is to break the main task into smaller, less energy-intensive tasks. This concept, known as Staging, plays a crucial role in improving the energy efficiency of energy-intensive processes.

While there are many examples of staging being utilized to improve energy efficiency (e.g., Compound Engines, Steam Engines, Pumps, and Compressors), this essay will focus on the wildly successful Jet Engine.

Almost a century ago, a significant shift in air travel began. At that time, planes were predominantly powered by propeller-piston motors, which were effective but had inherent limitations. These motors were continually optimized for their intended use, but they were fundamentally limited to a single stage of operation. They compressed the air once and propelled the plane forward.

Jet engine development took a significant leap forward in 1928 [1]. Since then, the concept has been aggressively developed and highly optimized. Today's jet engines showcase engineering excellence, utilizing staging to achieve remarkable levels of capability and efficiency. These engines use various types of staging, each with multiple stages, demonstrating the potential of relentless pursuit of system optimization.

The success of today’s air travel is attributed to the jet engine. A great example is the Rolls-Royce Trent family of engines. [2] These engines generally use three kinds of staging: an eight-stage IP compressor and a six-stage HP compressor, both driven by a single-stage turbine and a five-stage LP turbine. The jet engine is a testament to the power of relentless optimization, inspiring us to apply the same principles to other energy-intensive processes.

Gigaton-scale CO2 capture and removal will not be cost-effective until carbon capture processes, in general, and CO2 gas separation, in particular, are subjected to relentless system optimization. These energy-intensive processes must implement staging to every extent possible.

Today’s funding audiences for CO2 capture (including the DOE, Breakthrough Energy Ventures, Frontier Climate, etc.) are currently focused on single-stage CO2 capture. However, there is a potential for significant improvement in CO2 capture, akin to the relentless optimization seen in jet engines. This potential for improvement should instill a sense of optimism about gigaton-scale CO2 capture before 2040.

“It's very common, possibly the most common error of a smart engineer is to optimize the thing that should not exist” – Elon Musk [3]

This is an excellent observation by Elon Musk. Unfortunately, funding audiences for CO2 capture (Including the DOE, Breakthrough Energy Ventures, Frontier Climate, etc.) are focused nearly exclusively on supporting and optimizing technologies that should not exist (out of the lab).

The Pursuit of Engineering Excellence

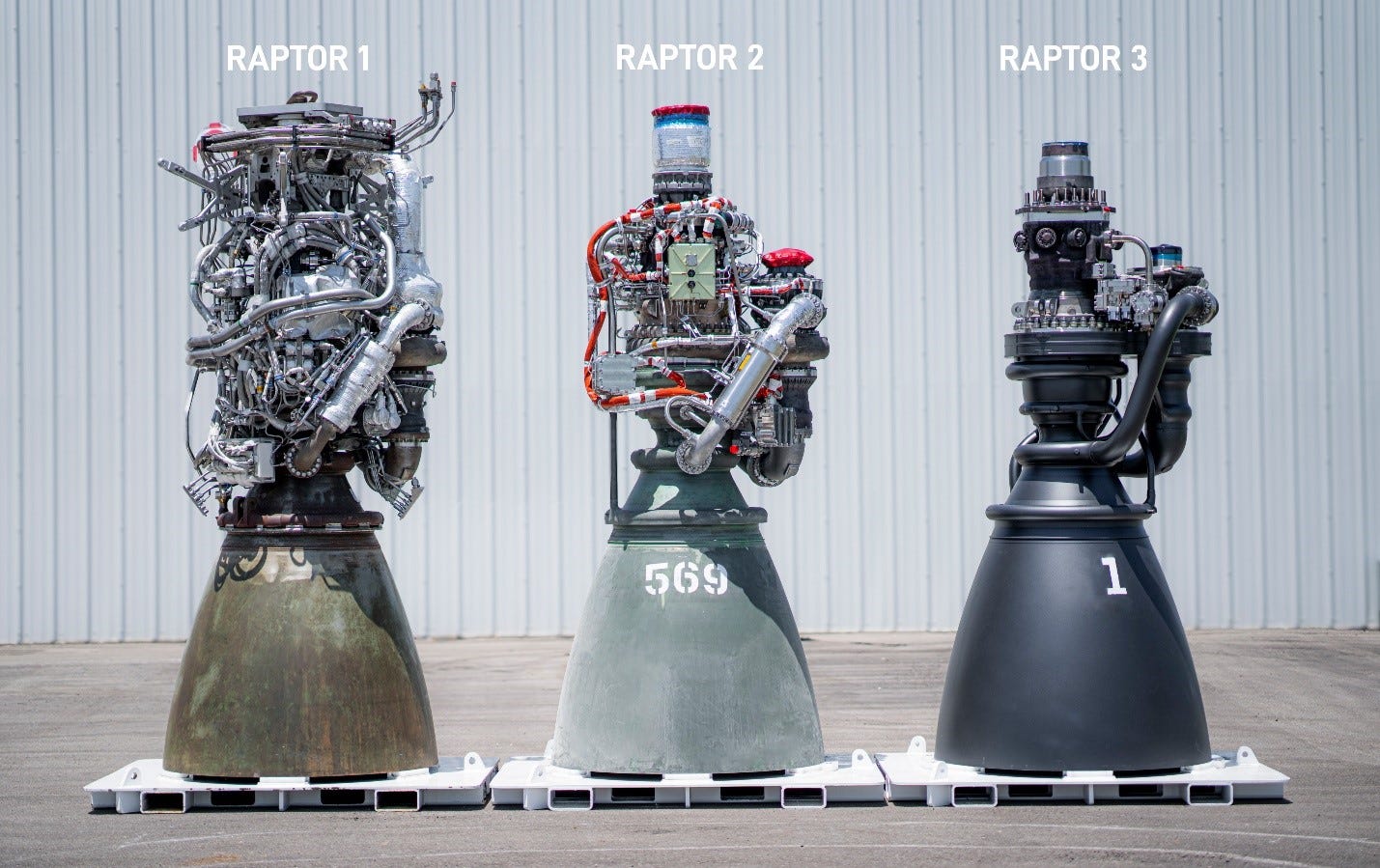

Above is a fascinating illustration that highlights the achievements possible by the relentless pursuit of engineering excellence. While not knowing the details, The Raptor 1 engine has the appearance of complexity that suggests manufacturing challenges, high costs, and low MTBF (mean time between failure). The Raptor 3 has the appearance of simplicity that suggests it cannot possibly even work. Without a doubt, the Raptor 3 will be cheaper to build and have much greater MTBF.

The evolution from Raptor 1 to Raptor 3 represents what is possible when engineers stop dictating terms to nature and instead optimize what nature has always offered.

Metaphorically, SpaceX's Raptor 1 engine represents the current DOE technologies for flue gas CO2 capture and CO2 DAC. The DOE is focused only on the effort to make the Raptor 1 engine cheaper to build and operate. The DOE is not interested in new designs or new approaches that could lead to the conceptual Raptor 3 engine.

Properly supported, I would bet SpaceX could develop a highly optimized CO2 capture technology that dramatically outperforms the DOE’s CO2 capture technologies. Furthermore, SpaceX will need to develop a universal CO2 capture technology when they get serious about developing long-term habitats for humans on Mars and the spaceships traveling between the planets.

SpaceX would be one partner in the “CO2 Capture Dream Team.” The other partner is Saudi Aramco. Together, these two organizations could develop and deploy a Universal CO2 capture technology. This Universal CO2 capture technology will be the arbitrarily scalable, cost-effective (DAC and CCS) technology for gigaton CO2 capture and the best possible CO2 capture technology for all On-World and Off-World applications.

Failure is an Option

Bluntly stated that after billions of dollars spent over the past several decades of research, the DOE has yet to produce a CO2 capture technology capable of cost-effectively removing CO2 from CO2-rich flue gases. This is a technological tragedy that will negatively affect tens of millions of lives in the near future.

The technologies produced by the DOE are not useable because “While mature, they are just not cost-effective” [5]. This statement is the official acceptance of failure as the technologies are unable to solve the problem they are needed to solve. The DOE is unable to develop a CO2 capture technology capable of Partial Pressure Staging and is content to have only developed single-stage CO2 capture technologies.

“Carbon capture has a long history. Of failure” [6]

The US government can reduce CO2 emissions using other tools. The effect of the DOE’s technology development failure is that the EPA is shutting down the entire US coal industry because of its high CO2 emissions [7]. Once that task is complete, the EPA can shut down other industries with high CO2 emissions. While the EPA’s efforts may eventually succeed, its efforts will have no effect on high CO2 emissions outside the US.

“Carbon Negative Shot is an all-hands-on-deck call for innovation in carbon dioxide removal pathways that will capture carbon dioxide (CO2) from the atmosphere…” [8]

As currently practiced, this statement is meaningless. The DOE is managing CO2 capture poorly, just as poorly as NASA and Boeing are managing the Space Launch System [9] and Starliner development programs [10]. It is past time for the US government to embrace a more effective approach to technology development to achieve the Carbon Negative Shot mission. Specifically, the DOE needs to embrace a broader innovation portfolio as well as SpaceX’s approach to innovation—Fail Fast, Learn, and Iterate.

[1] Jet Engines (stanford.edu)

[2] Rolls-Royce Trent - Wikipedia

[3] The most common error of a smart engineer- Elon Musk #shorts (youtube.com)

[4] SpaceX on X: "Raptor 3 (sea level variant) Thrust: 280tf Specific impulse: 350s Engine mass: 1525kg Engine + vehicle-side commodities and hardware mass : 1720kg https://t.co/zormSroZyh" / X

[5] Over-promising and under-delivering for half a century: CCS is still a risky and unproven technology – Geoengineering Monitor

[6] Carbon capture has a long history. Of failure - Bulletin of the Atomic Scientists (thebulletin.org)

[7] New EPA Regulations on Fossil Fuel Emissions Could Lead to Power Shortages | OilPrice.com

[8] Carbon Negative Shot Summit | Department of Energy

[9] Report slams Boeing for bad work, but not over the Starliner • The Register

[10] Boeing Starliner: What life is like for two astronauts in limbo in space | CNN

I totally agree with this essay. There are several problems with DOE and how they are trying to manage CO2 capture.

First as Mike has said they are only trying to optimize current methods of capture, mainly some form of mineralization and storage or mineralization to capture CO2 and demineralization to release the CO2. Both of these methods rely on mineral oxides or hydroxides that will form carbonates. The oxides or hydroxides require hefty energy inputs for their synthesis, energy that is usually supplied by burning a fossil fuel. This makes the process very inefficient for carbon capture.

Second. DOE is funding programs for transportation and long term storage of CO2 by building pipelines and injecting it into rock formations. This will also require fossil fuels making the capture process even more inefficient.

Third. DOE has allowed mission creep into the process. A group that applies for funding from DOE has their proposal partially rated on how well they comply with DEI guidelines and environmental justice guidelines. If the US government believes that CO2 is an existential threat to the world then all proposals should be rated on the solution to that threat not on who is doing the research or where it is being done.

CO2 can be an excellent feedstock for the chemical industry. After all plant life certainly uses it as a feedstock. Some day private industry will devise a method of converting CO2 to useful materials such as biodegradable polymers or solvents, but it will probably not be through the help of the US government because they will not recognize it as a solution to the problem.